+86 178 5514 5298

+86 178 5514 5298

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

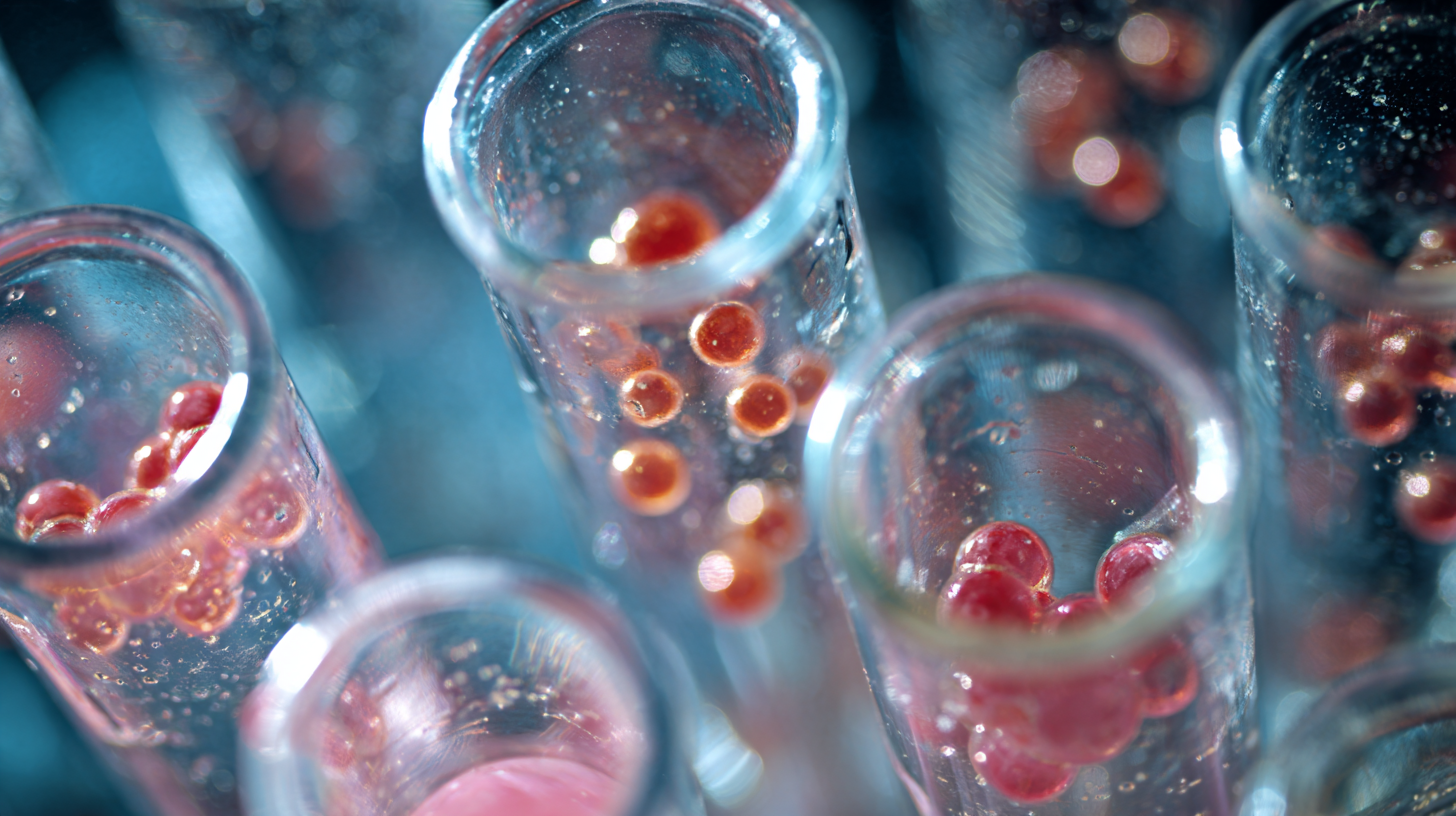

As we step into 2025, the laboratory supplies market is poised for significant advancements, particularly in the realm of specimen tubes, which play a crucial role in medical diagnostics and research. According to a recent report by MarketsandMarkets, the global laboratory tube market is projected to reach $2.3 billion by 2025, driven by the increasing demand for high-quality blood collection and storage solutions.

Innovations in specimen tube design, materials, and functionality are essential for meeting the evolving needs of healthcare professionals and researchers. This blog will explore the top strategies shaping the future of specimen tube technology, highlighting the latest innovations that promise to enhance sample integrity, improve patient safety, and streamline laboratory processes. As the landscape of laboratory supplies continues to evolve, staying informed about these emerging trends will be vital for industry stakeholders aiming to navigate the competitive market effectively.

As we approach 2025, the laboratory supplies industry is set to witness significant innovations in specimen tube design and functionality. One of the most prominent trends is the integration of smart technology into specimen tubes. These advanced tubes can monitor and record temperature, pressure, and even bar code labeling through built-in sensors. Such innovations enhance the accuracy of specimen tracking and ensure optimal storage conditions, minimizing the risk of contamination.

In addition to smart technology, sustainability is becoming a key focus in specimen tube manufacturing. Biodegradable materials are emerging as a viable alternative to traditional plastics, addressing both environmental concerns and regulatory pressures. Laboratories looking to stay ahead of the curve should consider sourcing tubes made from eco-friendly materials and advocating for sustainable practices within their supply chains.

In addition to smart technology, sustainability is becoming a key focus in specimen tube manufacturing. Biodegradable materials are emerging as a viable alternative to traditional plastics, addressing both environmental concerns and regulatory pressures. Laboratories looking to stay ahead of the curve should consider sourcing tubes made from eco-friendly materials and advocating for sustainable practices within their supply chains.

Tip 1: When selecting specimen tubes, prioritize those equipped with smart technology features for enhanced tracking and stability.

Tip 2: Evaluate your laboratory’s environmental impact and consider switching to biodegradable specimen tubes as part of your sustainability initiatives.

By embracing these emerging trends, labs can enhance operational efficiency while also contributing to a greener future.

In 2025, the landscape of laboratory specimen tubes is undergoing a remarkable transformation, driven by innovative materials that enhance both functionality and safety. Traditional tubes often faced limitations in durability and contamination risks, but the introduction of advanced polymers and composites is set to redefine their performance. These new materials offer superior resistance to breakage, enabling laboratories to handle specimens with increased confidence. Furthermore, innovations such as self-sealing mechanisms and integrated labeling technologies streamline the workflow, significantly reducing the potential for human error.

One of the standout innovations in specimen tube design is the use of biocompatible coatings that prevent sample degradation. These coatings not only preserve specimen integrity but also ensure that results are more reliable and reproducible. As laboratories strive for higher precision in their analyses, materials that safeguard against environmental influences are becoming indispensable. Additionally, sustainability is becoming a key consideration, with many manufacturers now exploring recycled and eco-friendly materials for specimen tube production, reflecting a broader commitment to environmental responsibility in laboratory practices.

| Innovation | Material Type | Key Features | Expected Use Cases |

|---|---|---|---|

| Biodegradable Specimen Tubes | PLA (Polylactic Acid) | Eco-friendly, reduces plastic waste | Clinical studies, environmental research |

| Smart Specimen Tubes | Conductive Polycarbonate | Integrated RFID for tracking | Inventory management, sample tracking |

| Antimicrobial Tubes | Silver-infused HDPE | Prevents microbial growth | Pathogen-rich environments, research labs |

| Vacuum Specimen Tubes | Modified Glass | Consistent vacuum performance | Blood collection, in vitro diagnostics |

| Revolutionary Seal Technology | Advanced Polymer Blends | Enhanced leak protection | Transport of liquid samples |

As we look ahead to 2025, the realm of laboratory supplies is set to undergo significant transformation, particularly in the category of specimen tubes. One of the most critical advancements revolves around enhancing specimen safety, an area that industry reports highlight as paramount for effective laboratory operations. According to the latest market analysis by Research and Markets, the global specimen container market is projected to reach USD 5.5 billion by 2025, driven largely by innovations that prioritize safety and reliability in specimen handling.

New features being introduced in specimen tubes include advanced leak-proof seals and antimicrobial coatings designed to reduce contamination risk. Recent studies indicate that up to 40% of specimen errors in clinical laboratories can be traced back to improper handling and storage conditions. By integrating smart technologies, such as RFID tags that monitor storage conditions, laboratories can ensure that specimens remain unadulterated throughout their lifecycle.

Moreover, a report by Grand View Research emphasizes that tubes equipped with color-coded caps will simplify sample identification, further reducing the likelihood of mix-ups during testing phases. With these innovations on the horizon, the future of specimen tubes looks promising for enhancing both specimen safety and overall laboratory efficiency.

As laboratories move towards a more sustainable future, the innovation of eco-friendly specimen tubes is becoming a key focus in 2025. Traditional specimen tubes, often made from plastic, contribute significantly to environmental waste.

However, the latest advancements are embracing biodegradable materials and recyclable designs, ensuring that laboratories can minimize their ecological footprint without compromising on quality or safety.

In the rapidly evolving landscape of laboratory supplies, the impact of Chinese manufacturing on specimen tube quality cannot be overstated. With an increasing demand for high-volume testing and sample collection, China's manufacturing capabilities have risen to meet global standards. This shift has allowed laboratories worldwide to access a diverse range of specimen tubes that not only meet stringent quality requirements but also offer cost-effective solutions. By leveraging advanced production techniques and stringent quality control measures, Chinese manufacturers are setting new benchmarks for reliability and precision in specimen collection.

However, the balance between global and local manufacturing is crucial in maintaining specimen tube quality. While Chinese manufacturers can produce them at scale, local manufacturers often provide bespoke solutions tailored to specific regional needs. This localization can lead to improved responsiveness and customization, ensuring that the unique requirements of various healthcare settings are met. Thus, laboratories must navigate the complexities of sourcing specimen tubes, considering both global efficiencies and local expertise to optimize the quality of their supplies. This interplay between global and local production will play a significant role in shaping the future of laboratory supplies.