+86 178 5514 5298

+86 178 5514 5298 Choosing the Right Container for Medical Specimen Transport: Why the 95kPa Bottle is the Ideal Solution

The Challenges of Medical Specimen Transport

Medical specimens are often sensitive to environmental changes, contamination, and physical damage. Key risks during transport include:

-

Pressure Fluctuations: Changes in air pressure (e.g., during air freight) can compromise container seals. -

Leakage: Improper sealing risks exposure to hazardous materials and cross-contamination. -

Temperature Variability: Some specimens require strict temperature control. -

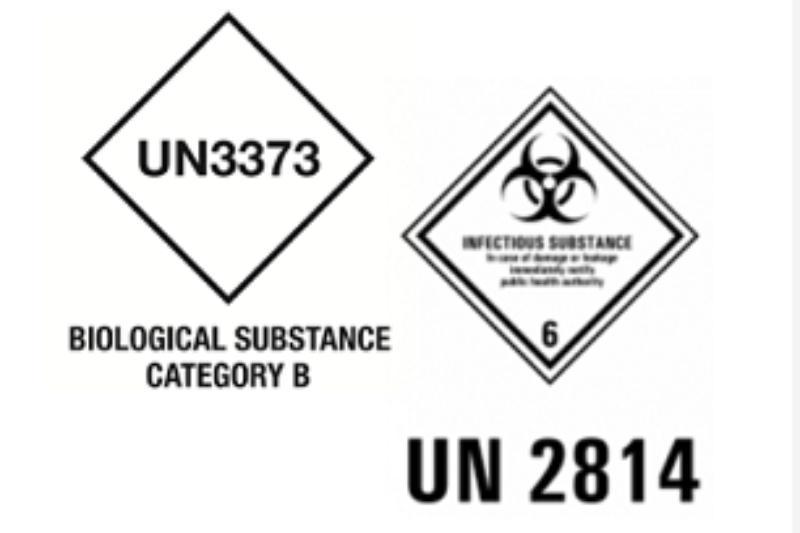

Regulatory Compliance: Containers must meet international standards (e.g., WHO, IATA, UN 2814/3373).

Why the 95kPa Pressure-Resistant Bottle Excels

Our 95kPa Bottle is engineered to address these challenges head-on. Here’s how it ensures safe and compliant specimen transport:

1. Unmatched Pressure Resistance

The 95kPa bottle is rigorously tested to withstand pressure differentials up to 95 kilopascals (kPa), making it ideal for air transport. Unlike standard containers that may fail under low-pressure conditions at high altitudes, our bottle maintains an airtight seal, preventing leaks and preserving specimen quality.

2. Leak-Proof Design

Featuring a double-layered screw cap and silicone gasket, the 95kPa bottle provides a hermetic seal even under extreme pressure changes. This design eliminates the risk of leakage, ensuring compliance with IATA Dangerous Goods Regulations (DGR) for Category B infectious substances.

3. Material Safety and Durability

Made from medical-grade polypropylene (PP), the bottle is chemically inert, shatterproof, and resistant to temperature fluctuations (-80°C to 121°C). It is compatible with autoclaving, simplifying sterilization and reuse.

4. Compliance with Global Standards

The 95kPa bottle meets or exceeds critical certifications:

-

UN Certification: Certified to UN 2814 (Category A) and UN 3373 (Category B) standards. -

ISTA 3E Testing: Validated for shock and vibration resistance during transit. -

CE & FDA-Compliant: Safe for medical and laboratory use.

5. Versatility

The bottle’s modular design supports:

-

Primary Containment: Direct storage of liquid or solid specimens. -

Secondary Packaging: Integration with absorbent materials and insulated boxes for temperature-sensitive shipments. -

Labeling: A writable surface for patient IDs, hazard symbols, and handling instructions. -

Use Cases: When to Choose the 95kPa Bottle -

Infectious Substance Transport: Ideal for Category B specimens (e.g., blood, urine, swabs). -

Biobanking: Safeguards DNA, RNA, and tissue samples during long-term storage or shipping. -

Pharmaceutical Trials: Secures clinical trial samples under variable transport conditions.

Best Practices for Using the 95kPa Bottle

-

Pre-Shipment Checks: Ensure the cap is tightly sealed and the gasket is intact. -

Cushioning: Use absorbent padding around the bottle in secondary packaging. -

Label Clearly: Mark “Biological Substance, Category B” and include emergency contact details. -

Documentation: Attach required shipping papers (e.g., waybill, safety data sheets).

Trust the 95kPa Bottle for Uncompromised Safety

In medical logistics, there’s no room for error. Our 95kPa Pressure-Resistant Bottle combines cutting-edge engineering with rigorous compliance to deliver a container that healthcare professionals can rely on. By choosing this solution, you’re not just meeting regulations—you’re prioritizing safety, accuracy, and peace of mind.

Ready to Upgrade Your Specimen Transport?

Contact our team today to learn more about the 95kPa Bottle or request a sample. Let us help you streamline compliance and protect what matters most.